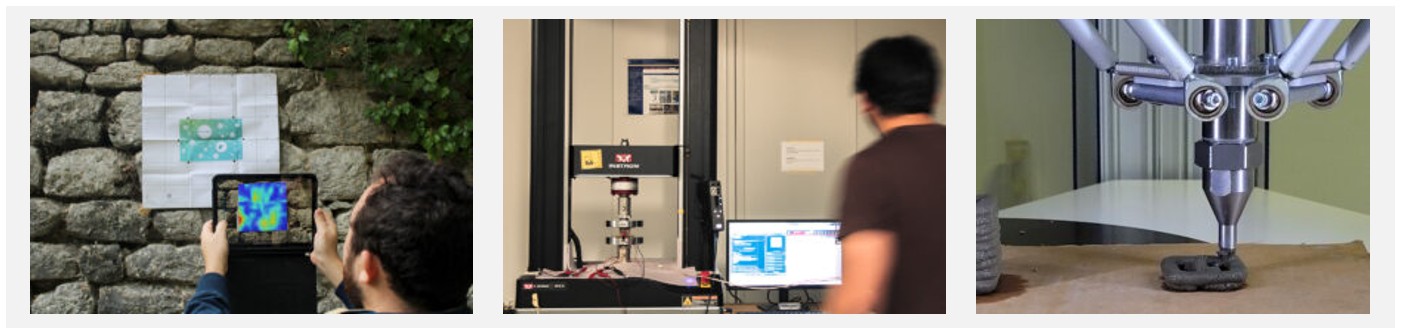

The Laboratory conducts mechanical tests on full-scale structural elements and laboratory-scale mock-ups of structures and infrastructures. Realistic structural settings are tested under laboratory conditions to characterize their mechanical response and/or simulate potential damage scenarios or degradation effects. Experimental applications of Structural Health Monitoring (SHM) systems involve traditional and innovative sensing technologies and monitoring strategies to study their effectiveness and detection capabilities. Research also investigates the 3D printing of cement- and clay-based construction materials, primarily to produce innovative sensing technologies for SHM applications. In addition, the Laboratory's activities are devoted to using drones and/or laser scanning technologies for the digital reproduction of existing structures and infrastructures (such as residential buildings, historical constructions, bridges, dams, and more), as well as for their visual inspection and health monitoring. In these last contexts, innovative approaches are developed for detecting and evaluating superficial structural defects and deformation states by combining photogrammetry and/or laser scanning techniques with artificial intelligence algorithms.

The Laboratory is equipped with a reaction structure composed of a floor and two orthogonal reaction walls, 8 m high, allowing the execution of pseudo-static and pseudo-dynamic tests on large-scale prototypes, with load application in the three principal directions. Another strong floor, 10 m x 10 m in plan, with a rigid steel portal frame, allows the execution of pseudo-static and pseudo-dynamic tests under bending and shear loading on large-scale prototypes, with load application in the vertical direction.

Actuators up to 1000 kN and a dynamometer up to 50 kN are available, operating under both displacement and force control using high-tech control units. Additionally, small and medium-sized 3D printers for cement- and clay-based construction materials are available. The equipment is available for contract work. Traditional visual inspections of existing structures and infrastructures for the evaluation of superficial defects and structural pathologies can be also performed upon request.

Recent posts

- Seismic Safety and Vulnerability at the Heart of the ANIDIS 2025 Conference: Assisi as a Symbol of History and Innovation – Sicurezza sismica e vulnerabilità edilizia al centro del Convegno ANIDIS 2025: Assisi simbolo di storia e innovazione

- A Chat with Prof. Liberato Ferrara – VITALITY Research Project

- Final Announcement: ANIDIS 2025 – The 20th Conference on Earthquake Engineering in Italy